The Chair of Resource Mineralogy looks back on a long history of using this analytical method. As early as the 1970s, one of Austria's first electron beam microprobes was operated in the laboratories of the Institute of Mineralogy and Petrology at the University of Leoben. The head of the institute at that time, the mineralogist Prof. Dr. Eugen F. Stumpfl, was considered one of the pioneers of microprobe analysis. Today's laboratory bears his name in his honour.

In the following years, the Chair of Resource Mineralogy was able to expand its expertise in the field of solid state analysis, and in 2007 the then most modern electron beam microprobe in Austria was purchased as part of the University Centre for Applied Geosciences Styria. Under the direction of Dr. Federica Zaccarini and Dr. Monika Feichter, Helmut Mühlhans and Maik Zimmermann as technicians, the laboratory continued to set international standards, e.g. in the analysis of new minerals, and is an integral part of teaching and research at the University of Leoben.

Equipment

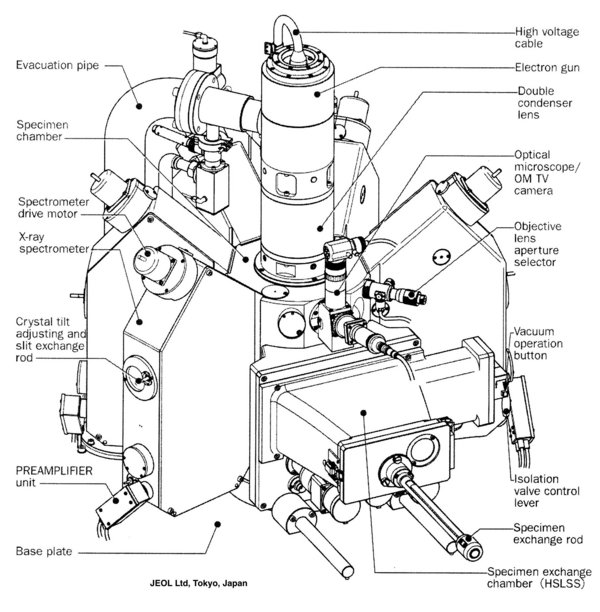

- JEOL Superprobe JXA 8200

- Secondary and backscatter electron image processing at magnifications from 40 to 300,000x

- High resolution elemental distribution images up to a size of 3200mm2

- Cathodoluminescence detector

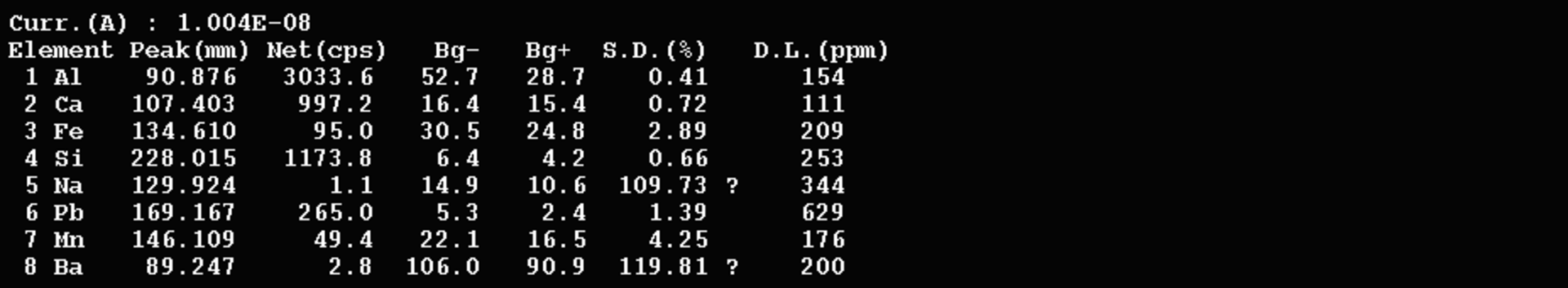

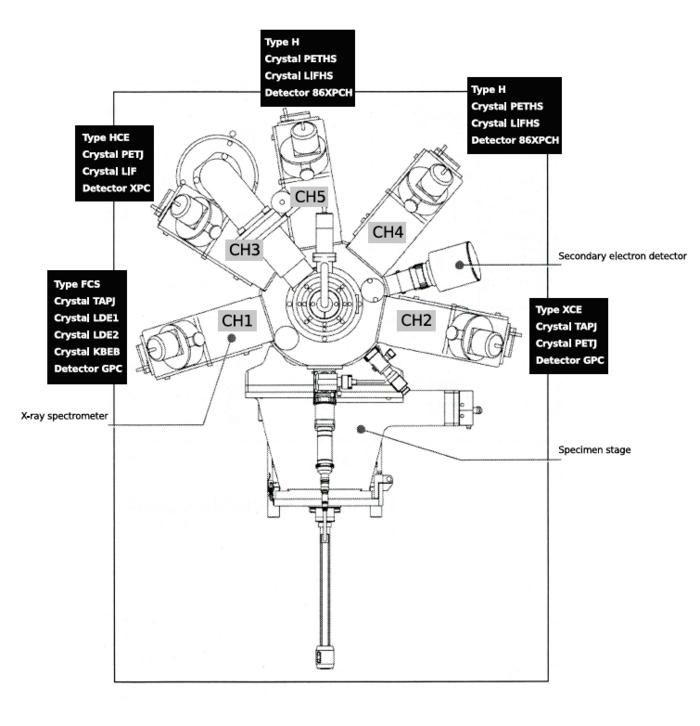

- 5 WDS spectrometers - analysis crystals: KBEB, LDE 1+2, TAP, PET and LIF (for quantitative determination of boron(Z5) to uranium(Z92))

- EDS detector: Si(Li) (for the qualitative determination of sodium(Z11) to plutonium(Z94))

Applications

Electron beam microprobe analysis is a non-destructive method for determining the chemical composition of the smallest components of solids close to the surface. Based on the fundamentals of electron microscopy combined with wavelength-dipersive spectroscopic (WDX) and energy-dispersive spectroscopic (EDX) analysis, we can, on the basis of characteristic element-specific X-rays, obtain qualitative and quantitative information regarding the chemical composition and texture of minerals and rocks, ores, synthetic crystals, metals, alloys, steels, slags, glasses, ceramics, electronic components, mineralised bones, skeletal and shell remnants of fossils, etc. are preserved.

With regard to the deposit research, geological and mineralogical focal points of the projects at the chair, the microprobe is mainly used for the petrological investigation of magmatic and metamorphic rocks, ore minerals and technogenic products such as slags. A research focus in recent years has been the analysis of new and rare mineral phases, e.g. platinum metals, gold minerals and rare earth minerals.

Requirements for the sample material

Due to the interaction with the electron beam and the high vacuum prevailing in the sample chamber, there are special requirements for the sample material. Only samples whose structure is not destroyed by the directed electron beam and whose physical properties are stable in the vacuum can be processed.

The possibilities of specimen formats depend on the dimensions of our specimen holders. It is possible to take round sections with a diameter of ≤ 2.5cm (1inch), 3cm and 3.8cm. For thin sections, we specialise in the "Giessen format" 28mmx48mm, but variations are possible here.

In order to apply the analytical capabilities of the EPMA method, the sample surface must be ground flat and finalised with a final polish of ≤ 1μm grain size.